Regulator Date Codes

In order to comply with best practice it is necessary to replace your pressure regulator at least 5 years after manufacture, or in accordance with manufacturer’s recommendations.

Although manufacturers and suppliers of regulators are not required to date mark regulators many adopt the best practice of doing so.

Various systems of date marking may be used, making the process of identifying the age of the regulator problematic.

Other equipment typically covered by BCGA codes of practice which should be changed at least every 5 years include flashback arrestors and high pressure flexible hoses used in mobile or manifold gas systems.

We are often asked why it is necessary to replace regulators after 5 years. This is a very good question – especially when on visual inspection the regulator appears to be undamaged and in good working order.

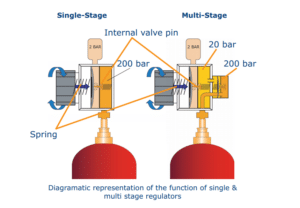

To answer this question you must bear in mind the internal construction of the regulator.

The internal workings contain springs and a rubber diaphragm, over time the components may deteriorate resulting in less effective pressure control.

The purpose of a regulator is to safely control the pressure of the gas from the cylinder through the system to point of use.

It is important to remember that regulators must only be used for the gas or gases for which it was designed and specified by the manufacturer – for example a propane regulator must not be used with acetylene.

Regulator date coding table, TS18 from the BCGA

Date marking codes vary between manufacturers. A useful document to help understand the codes is TS18 Date Marking of GAs Accessories from the BCGA.

Download TS18 here

Interested in training?

Pre-use checks including checking regulator dates codes are included in all our courses. Check out our range of Gas Safety training courses.

Codes of Practice

All users of compressed and cryogenics gases in the UK should comply with codes of practice issued by the BCGA, unless there is a compelling safety reason not to do so.

In this case, the user or owner of the system must put in place alternative procedures which are equal to or better than those stated in the BCGA codes of practice.